Digital platforms are revolutionizing the supply chain industry by facilitating unprecedented levels of collaboration. In today’s fast-paced and complex global market, the ability to quickly share information, make data-driven decisions, and adapt to changes is crucial. Digital platforms empower businesses to achieve these goals by providing a centralized, accessible, and secure space for supply chain partners to communicate, collaborate, and operate efficiently.

The transition from traditional supply chain management to digital collaboration represents a significant shift in how businesses approach logistics and operations. Traditional methods often rely on manual processes, which can be time-consuming, error-prone, and lack transparency. Digital collaboration, on the other hand, leverages technology to improve efficiency, reduce operational costs, and enhance overall supply chain transparency. This shift not only streamlines operations but also supports more agile and responsive supply chains capable of adapting to the dynamic demands of the global market.

This article aims to delve into the role of digital platforms in enhancing supply chain collaboration, exploring the benefits, and providing a roadmap for businesses looking to adopt these technologies. Through insights and actionable strategies, readers will learn how to effectively leverage digital platforms to foster stronger partnerships, improve operational efficiency, and drive growth in their supply chain operations.

The Importance of Digital Collaboration in Supply Chains

Enhancing Visibility and Transparency

Digital platforms offer an unparalleled advantage in enhancing visibility and transparency across the entire supply chain. By integrating data from various sources and making it accessible in real-time, stakeholders can gain a comprehensive view of operations, from procurement to delivery. This level of transparency enables better decision-making, as businesses can quickly identify and address bottlenecks, predict potential disruptions, and adjust strategies accordingly. Real-time visibility also enhances trust among supply chain partners, as information is shared openly, fostering a collaborative environment that benefits all involved.

Streamlining Communication and Processes

One of the most significant benefits of digital platforms is their ability to streamline communication and processes among supply chain partners. Digital tools facilitate seamless information exchange, eliminating the delays and misunderstandings that often accompany traditional communication methods. For instance, cloud-based platforms allow for instant updates on inventory levels, shipment statuses, and market demands, ensuring that all partners are on the same page. Additionally, these platforms can automate routine tasks, such as order processing and invoice generation, further streamlining operations and allowing businesses to focus on strategic initiatives. By enhancing communication and simplifying processes, digital platforms drive efficiency and reduce the likelihood of errors, contributing to smoother, more reliable supply chain operations.

Through digital collaboration, businesses can unlock new levels of efficiency, agility, and partnership within their supply chains. By understanding the importance of digital platforms and embracing their capabilities, companies can not only survive but thrive in the competitive global market.

Implementing Digital Platforms for Supply Chain Collaboration

Adopting digital platforms for supply chain collaboration requires a strategic approach to ensure that the technology aligns with business goals and enhances operational efficiency. Here’s how businesses can navigate the implementation process effectively.

Assessing Your Needs and Goals

Before diving into digital transformation, it’s crucial to assess your supply chain’s specific needs and goals. Start by mapping out your supply chain processes to identify areas where collaboration is lacking or inefficiencies are prevalent. Engage with different stakeholders, including suppliers, distributors, and customers, to gather insights on where improvements can be made. Set clear objectives for what you aim to achieve with digital collaboration, such as reducing lead times, improving inventory management, or enhancing transparency. This assessment will guide your search for the right digital platform that meets your specific requirements.

Choosing the Right Digital Platform

Selecting the right digital platform for supply chain collaboration is pivotal to the success of your digital transformation efforts. Look for platforms that offer scalability to grow with your business, ensuring they can handle increasing data volumes and expanding supply chain networks. Security is another critical factor, as the platform will handle sensitive information; it should have robust data protection measures in place. Additionally, user-friendliness is essential to ensure high adoption rates among your team and supply chain partners. Consider platforms that offer customization options, enabling you to tailor the solution to your unique business processes.

Integration with Existing Systems

Seamless integration with existing supply chain management systems is essential for a cohesive and efficient operational framework. Choose a digital platform that can easily connect with your current software, whether it’s an ERP system, inventory management software, or logistics tracking solutions. This integration allows for the automatic exchange of data between systems, reducing manual data entry and the potential for errors. Work with IT specialists to ensure a smooth integration process, and conduct thorough testing before fully rolling out the platform to identify and address any issues.

Enhancing Supply Chain Collaboration Through Digital Platforms

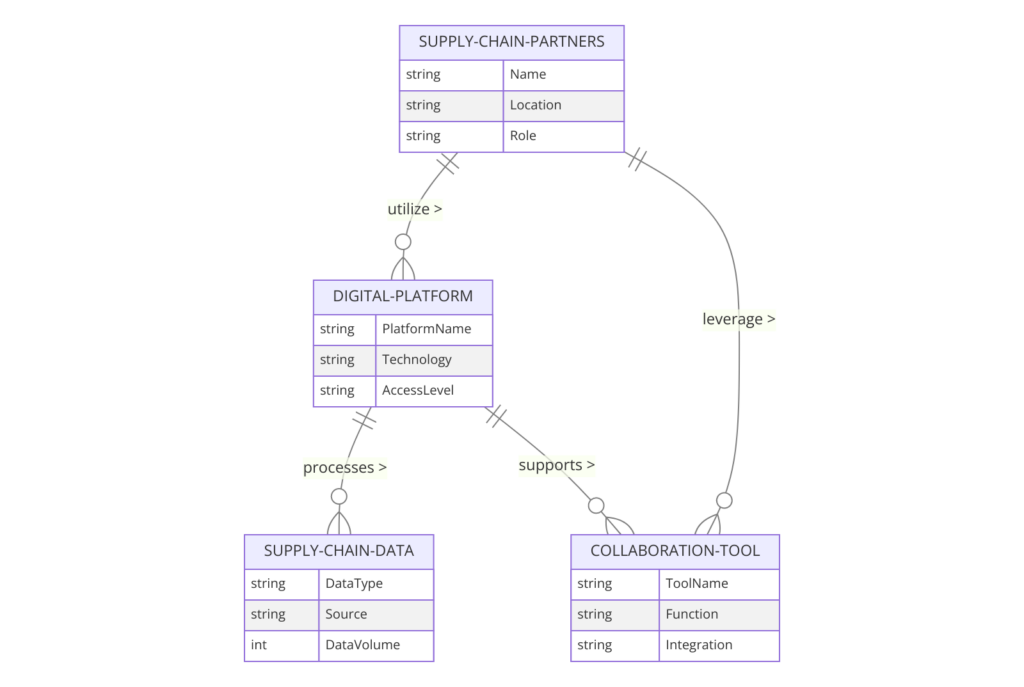

In the evolving landscape of global supply chains, the integration of digital platforms has emerged as a transformative force, driving unprecedented levels of collaboration and efficiency. As illustrated in the entity-relationship diagram, digital platforms serve as the central nexus connecting various supply chain partners, enabling a seamless exchange of information and collaborative decision-making.

Key Components of Digital Supply Chain Collaboration:

Supply Chain Partners: At the heart of the digital collaboration ecosystem are the supply chain partners, including suppliers, manufacturers, distributors, and retailers. Each plays a pivotal role in the movement of goods from production to consumption. Digital platforms facilitate direct and real-time communication among these partners, breaking down traditional barriers and fostering a more integrated approach to supply chain management.

Collaboration Tools: Essential to the digital platform are the collaboration tools that enable partners to share data, discuss strategies, and make joint decisions. These tools range from instant messaging and video conferencing to shared project management applications. They empower supply chain partners to work together more effectively, addressing challenges and identifying opportunities in real-time.

Data Processing and Analytics: Central to the digital platform’s functionality is its ability to process and analyze vast amounts of supply chain data. Through advanced analytics and artificial intelligence, the platform can offer predictive insights, optimize logistics operations, and enhance forecasting accuracy. This capability ensures that supply chain decisions are data-driven, reducing inefficiencies and better aligning supply with demand.

Integration and Interoperability: The diagram highlights the importance of integration and interoperability among the digital platform and existing supply chain systems. Seamless integration ensures that data flows freely across different software and hardware, eliminating data silos and enhancing overall supply chain visibility. This interconnectedness is crucial for maintaining an agile and responsive supply chain capable of adapting to changing market dynamics.

Security and Compliance: With the increased sharing of sensitive information, security and compliance emerge as critical concerns. Digital platforms must employ robust security measures, including data encryption and access controls, to protect against cyber threats. Additionally, compliance with regulatory standards ensures that supply chain operations adhere to legal and ethical guidelines.

Leveraging digital platforms for supply chain collaboration represents a significant leap forward in how businesses manage and optimize their supply chains. By fostering direct communication, facilitating data-driven decision-making, and ensuring seamless integration across systems, digital platforms enable supply chain partners to collaborate more effectively than ever before. As supply chains become increasingly complex and globalized, the adoption of digital collaboration platforms will be key to achieving resilience, efficiency, and competitive advantage.

5 Strategies for Maximizing Collaboration Through Digital Platforms

1. Centralizing Data Management

Centralized data management is key to enhancing accessibility and accuracy across the supply chain. Digital platforms can consolidate data from various sources into a single repository, making it easier for all stakeholders to access up-to-date information. This centralized approach improves decision-making and responsiveness, as partners can quickly obtain the insights they need without navigating through fragmented data systems.

2. Automating Key Processes

Leverage digital platforms to automate key supply chain processes such as procurement, invoicing, and shipment tracking. Automation not only reduces manual errors but also speeds up operations, freeing up staff to focus on more strategic tasks. For instance, automated procurement systems can reorder stock based on predefined criteria, ensuring inventory levels are optimized without manual intervention.

3. Fostering Partner Engagement

Active participation and engagement from all supply chain partners are crucial for effective collaboration. Encourage partners to regularly use the digital platform by demonstrating its benefits and providing training where necessary. Consider establishing forums or collaboration spaces within the platform where partners can share insights, discuss challenges, and develop solutions together, fostering a more cooperative and cohesive supply chain network.

4. Implementing Continuous Improvement Practices

Digital platforms offer valuable data that can be used for continuous analysis and improvement of supply chain operations. Utilize analytics and reporting tools to monitor performance, identify trends, and uncover areas for optimization. Encourage a culture of continuous improvement by regularly reviewing these insights with your team and supply chain partners, and implementing changes to enhance efficiency and responsiveness.

5. Ensuring Security and Compliance

Maintaining data security and regulatory compliance is paramount when collaborating through digital platforms. Ensure the platform complies with relevant data protection regulations and industry standards. Implement strict access controls and data encryption to protect sensitive information, and regularly audit the platform’s security measures to address any vulnerabilities.

By following these strategies and best practices, businesses can effectively leverage digital platforms to foster collaboration, streamline operations, and achieve a more resilient and responsive supply chain.

The Future of Digital Collaboration in Supply Chains

The evolution of supply chain management is increasingly intertwined with the advancements in digital technologies. The future of supply chain collaboration is being shaped by several key technologies and trends that promise to revolutionize how businesses interact, share information, and work together across the global supply chain network.

Emerging Technologies and Trends

The forefront of this revolution features blockchain, artificial intelligence (AI), and the Internet of Things (IoT). Blockchain offers a level of transparency and security previously unattainable, allowing for real-time tracking of products and transactions with an immutable record. AI and machine learning are transforming decision-making processes, providing predictive analytics to foresee and mitigate potential disruptions. The IoT connects physical assets to digital networks, enhancing visibility and control over the entire supply chain. Together, these technologies foster a more integrated, intelligent, and responsive supply chain ecosystem.

Building a Culture of Collaboration

For digital collaboration to flourish, cultivating a corporate culture that embraces innovation and digitalization is crucial. This culture encourages open communication, knowledge sharing, and continuous learning. By valuing collaboration over siloed operations, companies can leverage collective intelligence and creativity to solve complex challenges, innovate, and drive value. Leadership plays a pivotal role in championing this cultural shift, demonstrating commitment to digital collaboration and providing the necessary resources and support to foster an environment where it can thrive.

Challenges and Solutions

Adopting digital collaboration platforms comes with its set of challenges, including data security concerns, integration complexities, and resistance to change. Overcoming these obstacles requires a strategic approach, starting with selecting platforms that prioritize data security and offer robust encryption and access controls. Ensuring seamless integration with existing systems demands a thorough evaluation of compatibility and flexibility. To address resistance to change, comprehensive training and change management initiatives can help stakeholders understand the benefits and get on board with the new processes.

FAQs on Leveraging Digital Platforms for Supply Chain Collaboration

What are the key features to look for in a digital collaboration platform?

Essential features include real-time data sharing, scalability, user-friendly interfaces, robust security measures, and integration capabilities with existing systems. Flexibility to customize and adapt the platform to meet specific industry needs is also crucial.

How can small to medium-sized enterprises (SMEs) benefit from digital supply chain collaboration?

SMEs can achieve greater operational efficiency, improved decision-making, and enhanced competitiveness by leveraging digital platforms. These tools provide SMEs access to the same level of data and collaboration opportunities as larger companies, leveling the playing field.

What are the common pitfalls in digital supply chain collaboration and how to avoid them?

Common pitfalls include inadequate training, poor data quality, and lack of integration. Avoid these by investing in comprehensive training programs, maintaining high data quality standards, and ensuring the platform integrates well with existing systems.

Can digital collaboration platforms be customized to fit specific industry needs?

Yes, many digital collaboration platforms offer customization options to cater to specific industry requirements. This customization ensures that the platform aligns with unique operational processes and collaboration needs.

In Conclusion

Throughout this exploration of leveraging digital platforms for supply chain collaboration, we’ve delved into strategic approaches, technological innovations, and the cultural shifts necessary to embrace digital collaboration fully. The integration of blockchain, AI, and IoT technologies heralds a new era of supply chain management, characterized by unprecedented transparency, efficiency, and responsiveness. As we look to the future, the adoption and adaptation to these digital tools will be paramount for businesses aiming to remain competitive and thrive in the increasingly digital and interconnected global marketplace. The journey towards digital collaboration in supply chains is not without challenges, but the potential rewards for operational excellence, innovation, and growth are immense.