Artificial Intelligence (AI) is revolutionizing the way supply chains operate, bringing unprecedented levels of efficiency, accuracy, and responsiveness. As global supply chains become more complex and the demand for faster, more reliable delivery grows, businesses are increasingly turning to AI to optimize their operations. This article explores the transformative power of AI in supply chain optimization, detailing how it enhances demand forecasting, inventory management, logistics, and decision-making processes. By leveraging AI, companies can not only streamline their operations but also gain a competitive edge in an ever-evolving market. The implementation of AI in supply chain management is not just a technological upgrade but a strategic transformation that can lead to significant improvements in operational efficiency and customer satisfaction.

Enhancing Demand Forecasting

AI significantly improves demand forecasting by utilizing advanced algorithms and machine learning models to analyze vast amounts of data, including historical sales data, market trends, and even social signals. Traditional demand forecasting methods often rely heavily on historical data and human intuition, which can fall short in capturing rapidly changing market dynamics. AI, however, can predict demand with a high degree of accuracy, allowing businesses to optimize their procurement strategies, reduce holding costs, and minimize the risks of stockouts or overstocking. For instance, AI-driven demand forecasting helps companies anticipate market trends and adjust their inventory levels accordingly, ensuring they can meet customer demand promptly and efficiently. This predictive capability not only enhances inventory management but also allows for better financial planning and resource allocation, ultimately improving overall business performance.

Optimizing Inventory Management

AI transforms inventory management by providing real-time insights into stock levels and automating the reordering process to prevent stockouts. This technology helps businesses maintain optimal inventory levels, reducing storage costs and minimizing waste. AI systems can predict when products are likely to run out and automate reordering based on anticipated demand. This capability ensures that the right products are available at the right time, enhancing customer satisfaction and operational efficiency. Moreover, AI can identify patterns in inventory data, helping businesses understand and respond to seasonal variations and market trends more effectively. By automating inventory management, businesses can reduce the labor costs associated with manual inventory checks and reorders, leading to more streamlined and cost-effective operations.

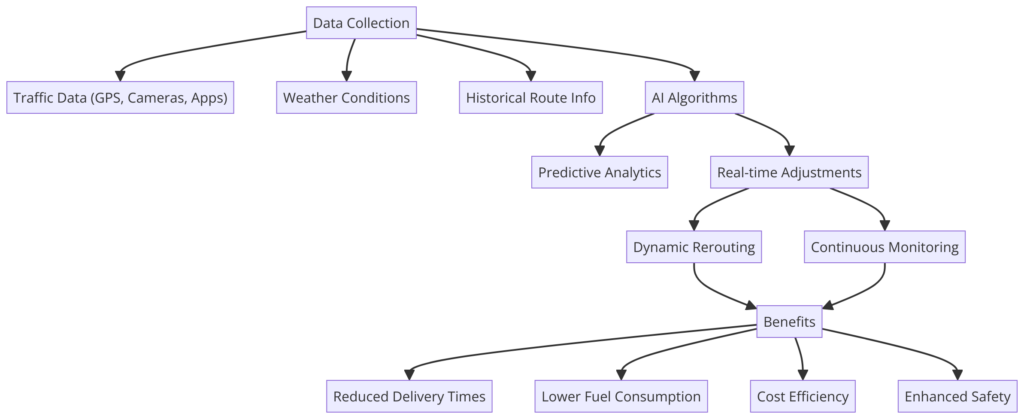

Improving Logistics and Transportation

AI plays a crucial role in optimizing logistics and transportation by analyzing multiple factors such as traffic patterns, weather conditions, and delivery routes. This analysis enables logistics companies to plan the most efficient routes, reducing delivery times and fuel consumption. AI-driven route optimization not only enhances delivery timelines but also minimizes operational costs. For example, AI systems can adjust delivery routes in real-time based on current traffic conditions, ensuring that goods are delivered promptly and efficiently. This capability is particularly valuable in urban areas where traffic congestion can significantly impact delivery schedules. Additionally, AI can optimize the loading and unloading processes, ensuring that vehicles are utilized to their maximum capacity, thereby reducing the number of trips needed and further cutting costs.

Enhancing Supply Chain Visibility

AI enhances supply chain visibility by providing real-time insights into every aspect of the logistics chain, from warehouses to final destinations. This transparency allows businesses to monitor the movement of goods, manage inventory levels, and track delivery status more effectively. AI-powered systems can detect potential disruptions in the supply chain, such as delays or bottlenecks, and alert managers to take corrective action promptly. Enhanced visibility also improves collaboration among supply chain partners, ensuring that all stakeholders are informed and can make data-driven decisions. This level of transparency is crucial for maintaining efficiency and reliability in complex supply chains, as it allows for proactive management and quick resolution of issues.

Data-Driven Decision Making

One of the most significant advantages of AI in supply chain management is its ability to provide data-driven insights that enhance decision-making processes. AI algorithms can analyze data from various sources, identify patterns and trends, and generate actionable insights. These insights enable supply chain managers to make informed decisions about logistics routes, inventory levels, and procurement strategies. By leveraging AI, businesses can optimize their operations, reduce costs, and improve service levels. AI’s predictive capabilities also allow companies to anticipate and mitigate potential risks, such as supply chain disruptions or changes in market demand. This data-driven approach ensures that decisions are based on accurate and timely information, leading to better outcomes and increased operational efficiency.

Implementing AI in Supply Chains

Implementing AI in supply chain operations requires careful planning and strategic integration. The first step is to identify the areas within the supply chain that can benefit most from AI, such as demand forecasting, inventory management, or logistics optimization. Businesses must ensure they have access to high-quality data, as the effectiveness of AI systems depends on the accuracy and reliability of the data they analyze. Additionally, companies need a robust technical infrastructure to support AI technologies and a skilled team to manage and maintain these systems. Training staff and continuously refining AI models based on performance feedback are essential for successful implementation. Furthermore, businesses should establish clear objectives and metrics to measure the impact of AI on their supply chain operations, ensuring that the technology delivers tangible benefits.

Overcoming Challenges

While AI offers numerous benefits, its implementation in supply chain management also presents challenges. High initial investment costs, data security concerns, and the need for skilled personnel are significant hurdles that businesses must overcome. Ensuring data privacy and protecting sensitive information from breaches is crucial when integrating AI systems. Additionally, companies must address ethical considerations and potential biases in AI algorithms to ensure fair and transparent decision-making. Despite these challenges, the long-term benefits of AI in enhancing supply chain efficiency, reducing costs, and improving customer satisfaction make it a worthwhile investment. Companies must develop a comprehensive strategy that addresses these challenges and leverages AI’s potential to drive supply chain transformation.

In Conclusion

The transformative power of AI in supply chain optimization cannot be overstated. By enhancing demand forecasting, optimizing inventory management, improving logistics, and providing data-driven insights, AI enables businesses to streamline their operations and gain a competitive edge. While the implementation of AI presents challenges, the benefits it offers in terms of efficiency, cost reduction, and customer satisfaction make it an indispensable tool for modern supply chain management. As businesses continue to navigate the complexities of global supply chains, leveraging AI will be crucial for achieving operational excellence and driving long-term success. By embracing AI, companies can transform their supply chains into agile, responsive, and efficient networks that meet the demands of today’s dynamic market environment.